JAY PHARMA EQUIPMENTS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to JAY PHARMA EQUIPMENTS

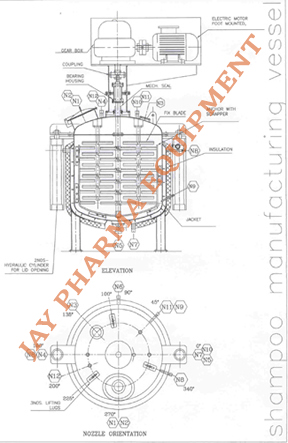

Shampoo Manufacturing Plant

Shampoos are typically viscous liquids, either clear or opaque (pearlised), containing 20–40% solids, adjusted to approximately pH 5.5. Most, but not all, have viscosities in the ratio of 500–1500 centipoise. A hair shampoo may be defined as a detergent specifically formulated for the washing of hair, and packaged in a user-convenient form. Typically, a shampoo must clean well, rinse easily, impart gloss to the hair, minimise tangle and not damage the hair structure, or the scalp or the eyes.

MANUFACTURING PROCESS

Shampoos are manufactured by simple slow blending in a stirred vessel. The vessel may be jacketed for heating. Vessels are normally closed type and subjected to vacuum to avoid excessive foaming when foaming agent is added. For best results contra type rotating stirrer is best used for shampoo manufacturing.

Ingredients are weighed or metered incrementally into the mixing vessel, with thorough mixing between each addition. A moderate amount of heat is used to reduce the viscosity and so facilitate ease of mixing.

Some pearlising agents are waxy solids at ambient temperature and require melting in a premixing vessels before use. Demineralised water is most commonly used in order to minimise contamination of the product.

No further processing is required after blending, & perfuming and the product may be packed off directly from the mixing vessel. Or may be transferred to storage vessels from where they are transferred to the filling machines.

Many companies make the bases for the shampoos where they do all the premxing of surfactants, sles, other ingredients and sell the same to major industries These industries are mainly called the formulators and in this second level processing will involve only the addition of water, colour and fragrance. In case of ayurvedic or herbal shampoos, they add their propriety formulae ingredients themselves so that no one knows the exact nature of ingredients and its details.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.